Joseph K. Gredder

Built from scratch by JGredder

I'm a Bioengineer

Mammalian and Microbial

Large and Small Scale

I'm a Software Guy

Creative and Technical

Some Examples of my Work

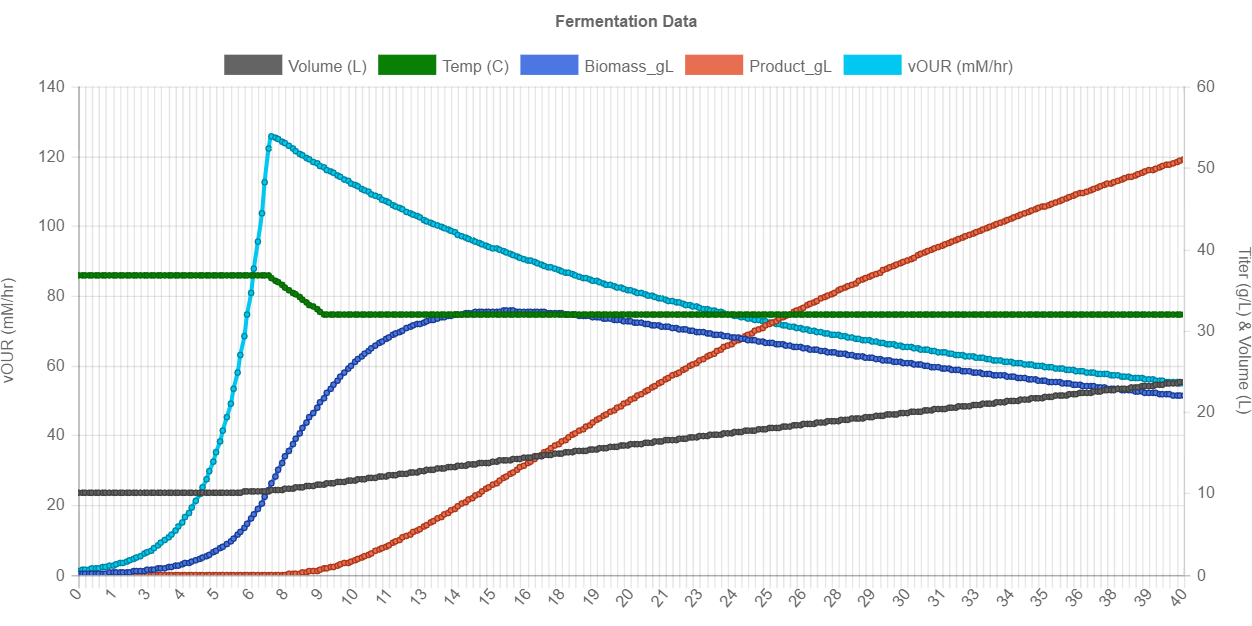

Bioprocess Model

A model simulating the production of bioproducts from micro-organisms

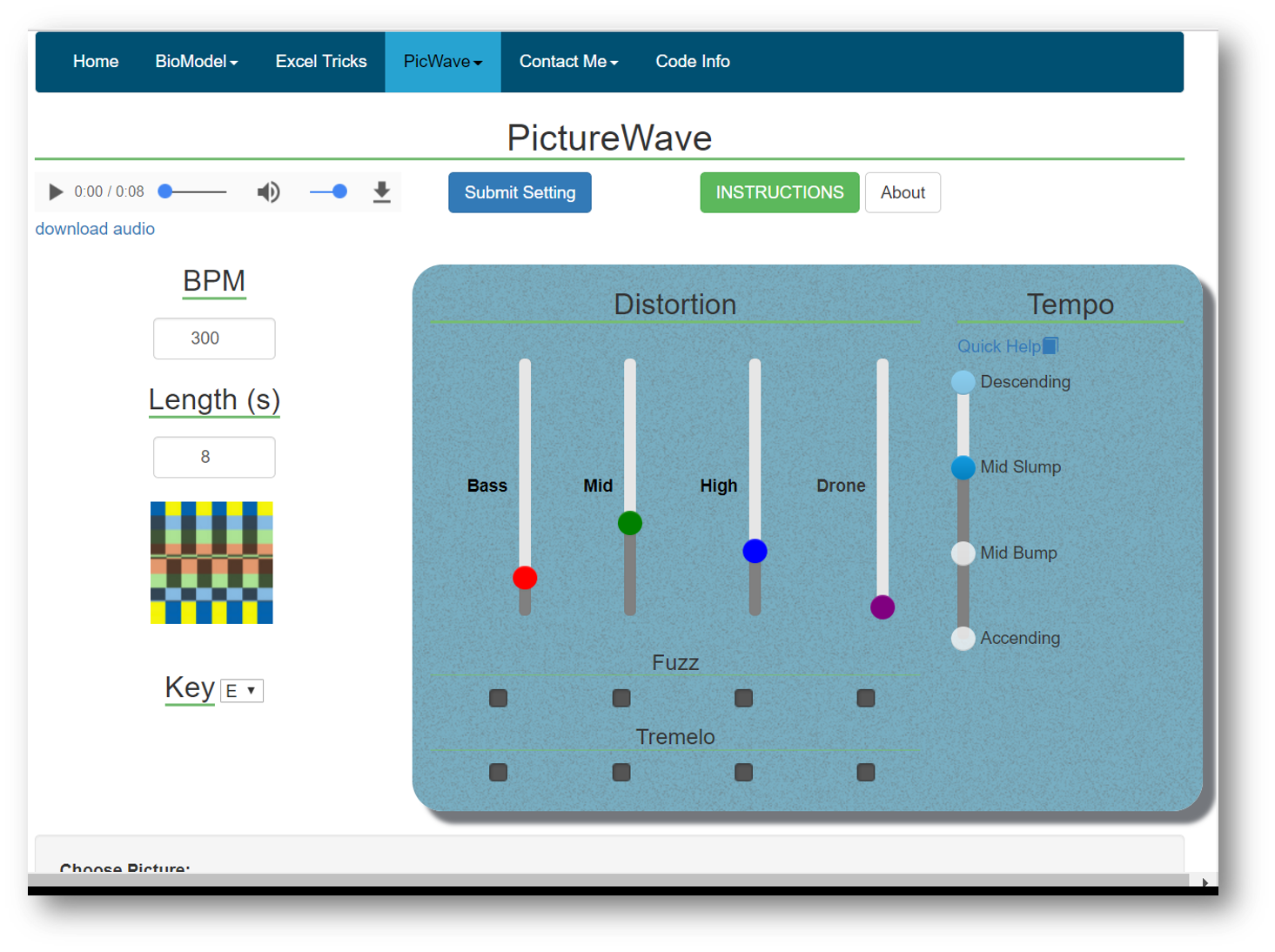

Picture to a Sound

An interactive web-app that turns your picture into a sound with various effects

About

I was born in NY, but local to San Diego, CA. I've been schooled in biotechnology and bioengineering. I've been playing and creating music all my life, and I am a fan of all things creative.

Professional Experience

B.S. Biotechnoloy, M.E. Biochemical Engineering

With a strong background in molecular biology and biochemistry, and a masters in biochemical engineering, I’m well suited to work at the interface of research and manufacturing. I have extensive hands-on experience with bioreactors, analytical instruments, metabolic engineering and genetics. I’ve personally batched and ran over 1,200 bioreactors ranging from 1 L to 250 L, along with assisting in the transfer of processes to commercial-scale production. I’ve designed and optimized media and processes for both bacterial and mammalian cell cultures. I’ve also created many strains myself and transfected various cell lines. In addition, I’m skilled at scripting software; meaning that I can trouble-shoot technical problems along with developing custom designed processes and automation. The same skills used in trouble-shooting and developing processes, I apply to data analysis and modeling. I have a creative outlook on science, and apply the latest topics to deliver quality results.

At BASF I am the point person for the digitalization piloting effort for fermentation in San Diego to collect and analyze offline and online data for eventua global integration. I author SOPs for the scale up and scale down of bioprocesses from research to manufacturing from internal groups and 3rd parties. I also interact with regulatory to ensure that the proper documentation is produced, reviewed, and in compliance with current standards. All of the aforementioned activies are to support a smooth and succinct transition of research technology to commercial production.

At Agensys inc. I was the lead of a project that realized a 4-fold increase in titers over the control. I created advanced templates for data acquisition, analysis and presentation, along with logging 7 years of past data into the new formats. I worked with Sartorius 3 L and 200 L reactors, GE WAVEs, Thermo (disposable) 250 L and 50 L reactors, and Finesse, MFCS and DeltaV systems.

At Metabolix inc. I made sure that information between R&D, process development, and manufacturing was presented to each party succinctly and in the right manner. I’ve screened over 1000 strains and successfully transferred many to manufacturing, along with creating several strains myself. I’ve scaled up the processes to the 50,000 L scale using logic that I scripted, and scaled down the process to mimic large-scale conditions. At all companies I wrote official reports and presented the findings to a wide range of audiences, including international affiliates.

Skills

Bioengineering

Microbial and Mammalian Cell Culture, Data Analysis & Optimization, Dynamic Process Modeling, Process Scale-up, Process Control Systems and Automation, Metabolic Engineering, Molecular Biology, Analytical Chemistry

Programming & Software

Python, VB.NET, VBA (macros), MATLAB, JavaScript, Django, HTML/Bootstrap, CSS, Linux, MS Excel, ProTools

Other

Guitar, Banjo, Mandolin, Cooking, Hiking, Running, Beach Volleyball, Travel and Learning Languages (Spanish & Russian)